No, the compressor must be a 11 BAR or 165 psi maximum pressure unit in order to maintain at least 10 BAR or 145 psi minimum pressure during the strenuous vacuum test cycle. Additionally, the filtering system for the compressor must remove both oil and particulates from the compressor lines to protect the Proofmaster from being damaged and prevent an expensive repair.

-

- Band Pin Assortments

- Brand Specific Assortments

- Case Tube Assortments

- Clips for Pushers Assortments

- Crown Assortments

- Dial Feet Assortments

- Dial & Timing Washer Assortments

- Findings Assortments

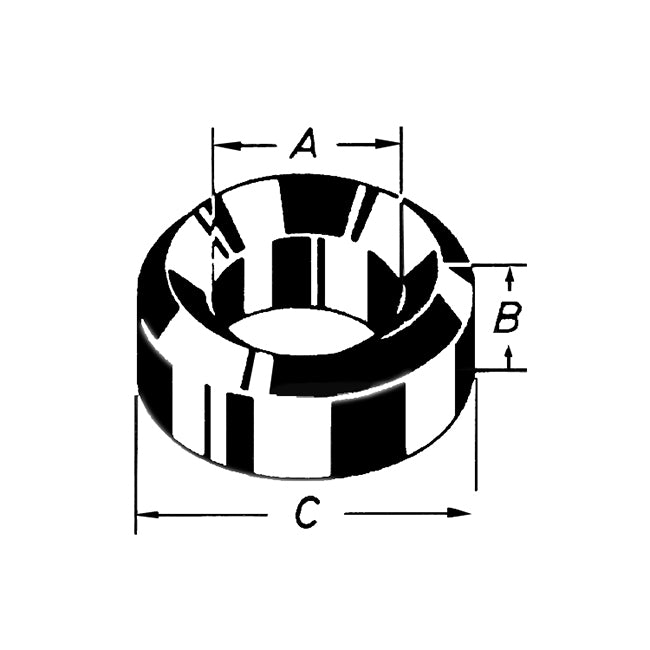

- Gasket Assortments

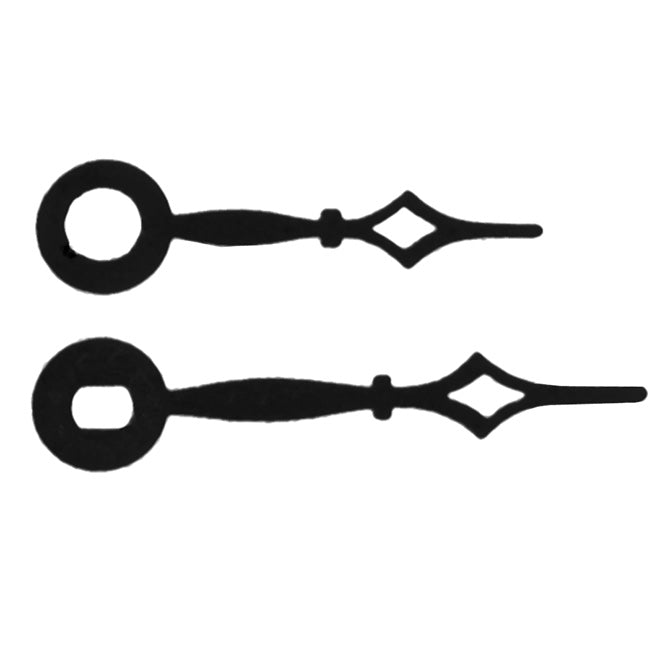

- Hand Assortments

- Movement Holder Assortments

- Pusher Assortments

- Screw Assortments

- Spring Bar Assortments

- Stem & Crown Posts Assortments

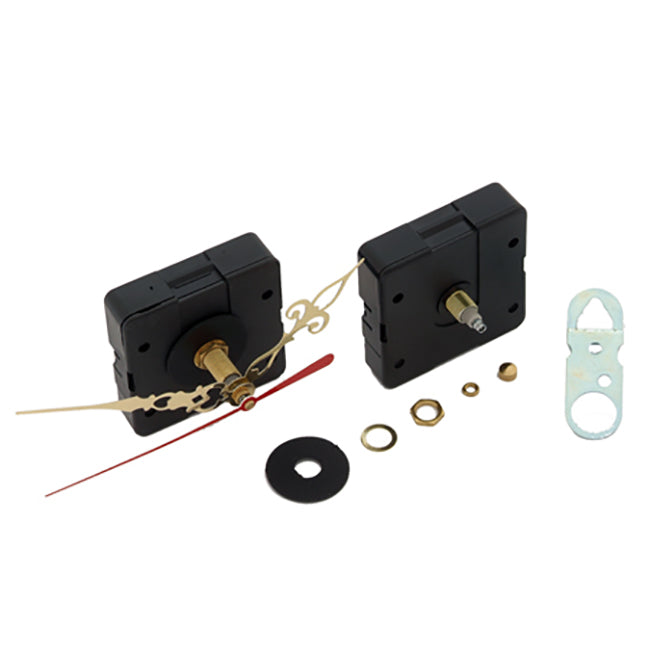

- Watch Movement Assortments

- Wire Assortments

-

-

- Login